LWL series horizontal spiral screen filter centrifuge

Date of issue:2020-04-27 Views:715

Main feature

Unmanned operation, continuous operation

The solids remaining on the net after separation and dewatering are continuously discharged to the outside of the machine by spiral blades to achieve unmanned operation and continuous operation;

Excellent dehydration performance

The residual solids on the net are discharged by the spiral blade within about 1 second. Therefore, the solids on the net become thinner, reduce the filtration resistance, and ensure good dehydration performance.

Low power consumption and large processing capacity

In order to reduce the discharge resistance of solid matter, the filter cartridge has a certain inclination angle (dehydration angle). The use of inclined angles and spiral blades reduces solid discharge resistance. It not only greatly improves its emission efficiency, but also has the advantages of low power consumption and large processing capacity.

Compact and compact machine

The assembly that makes up each part makes the machine more compact. Compared to the processing capacity, the machine is small and light. Stable operation even if flow rate and concentration change.

Generally speaking, when the flow rate or concentration changes drastically, the solid layer becomes uneven and vibration occurs. The LWL centrifuge uses the helical rotating blades to forcibly form a uniform solid layer to make the machine run stably.

Net suitable for processing

Through the experience accumulated in production, we provide the most suitable net for various treatments.

Easy to observe dehydration state

Even if the machine is running, the state of separation and dehydration can be observed through the front view mirror.

Special specifications

Special specifications can be customized according to customer requirements.

Application field

Mainly used in adipic acid, thenardite, AH-salt, ammonium persulfate, gypsum, ammonium nitrate, ammonium phosphate, ammonium sulfate, ammonium carbonate, ammonium sulfide, ion exchange resin, sodium chloride, anthracene, sodium chlorate, aspirin , Calcium formate, manganese sulfate, borax, methyl cellulose, sodium metaborate, sodium formate, sodium nitrate, sodium perborate, sodium phosphate, citric acid, sodium sulfate, polystyrene, sodium tetraborate, polystyrene alcohol, large Soda, copper sulfate, potash (potassium carbonate), tartaric acid, crystalline soda, potash, trisodium phosphate, potassium bicarbonate, zinc sulfate, pentaerythritol, plastic granules, glacial acetic acid, potassium chloride, potassium pentasulfide, potassium phosphate , Potassium sulfate.

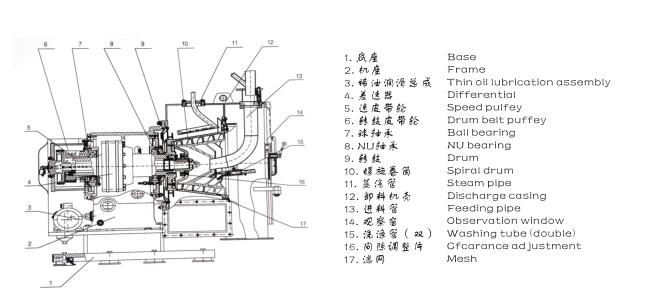

Schematic

Technical Parameters

Model

Feed quantity(m/h)

Power(KW)

Speed

(r/min)

Separtion coneffivent

(fr)

Dimensions

L × w × H(mm)

Weight

(kg)

LWL200

1.5

3

4350

2110

700×880×570

230

LWL250

3.5

5.5

3700

1913

910×1050×800

560

LWL320

7

7.5

3300

1950

940×1165×950

700

LWL350

10

11

2800

1530

1170×1360×1085

900

LWL400

15

15

2900

1880

1150×1500×1150

1000

LWL450

20

22

2500

1570

1390×1500×1315

1100

LWL520

25

30

2200

1406

1480×1920×1470

1800

LWL600

35

37

2200

1623

1560×2000×1470

2000

LWL700

50

55

1800

1400

2150×2100×1650

4000

LWL1000

100

90

1600

1400

2600×2700×2600

8000