PBL series flat plate centrifuge

Date of issue:2020-04-26 Views:606

Working principle

The PBL series is a centrifuge designed and produced in accordance with the requirements of the national pharmaceutical production GMP specification, especially for the production of sterile rooms. The centrifuge special explosion-proof motor is equipped with frequency conversion speed regulator to realize the stepless speed regulation of the centrifuge. The braking unit and braking resistor are electrically braked without wearing parts. A work cycle can be completed with dynamic or static feeding.

Performance and use

The machine has a compact structure, beautiful appearance, and a fully enclosed structure design to avoid cross-contamination of materials and improve the working environment. Flat structure, easy to clean. It is suitable for solid-liquid separation of suspension, and can be used for the separation of toxic, harmful, flammable and explosive materials.

Main feature

1. Large clamshell structure, easy to clean.

2. The liquid damping shock absorption system has a small impact on the surrounding area.

3. No wearing parts, compact structure.

4. Especially suitable for production in a sterile room.

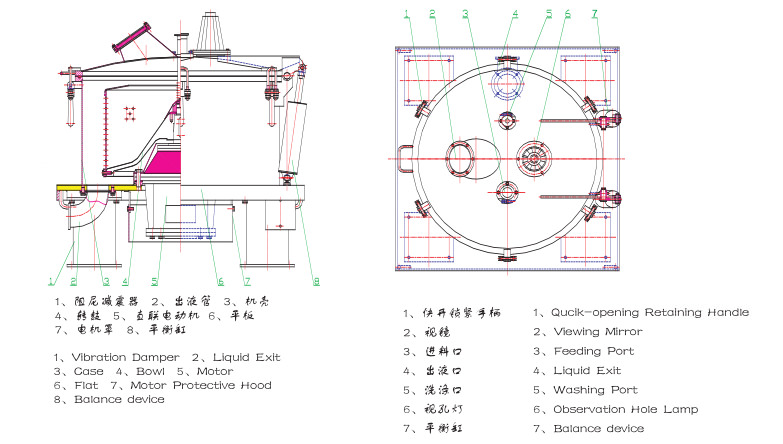

Schematic

Technical Parameters

Items

PBL300

PBL450

PBL600

PBL800

PBL1000

PBL1200

PBL1250

Drum diameter (mm)

300

450

600

800

1000

1200

1250

Drum height (mm)

160

300

320

400

420

500

500

Drum speed (r / mm)

2845

2000

1500

1500

1000

1000

1000

Separation factor (Fr)

1360

1008

756

1008

560

672

700

Working volume (L)

5

20

45

100

140

250

300

Loading limit (kg)

7.5

30

70

135

200

350

400

Motor power (kw)

0.75

3

4

7.5

11

18.5

18.5

Dimensions (L × W × H) mm

630 × 630

× 640

900 × 900

× 1000

1000 × 1000

× 1070

1200 × 1200

× 1180

2000×1500× 1950

1800 × 1800

× 1380

1800 ×1800

× 1380

Weight (kg)

250

600

1000

1500

2000

3000

3500

Opening height (mm)

1030

1470

1700

1940

2250

2590

2650